产品详情

详细信息

CYZ-A型自吸式离心泵概述Overview 上海帕特泵业制造有限公司生产的CYZ-A自吸式离心油泵是根据国内外有关技术资料经消化、吸收、改进后研制而成的最新泵类产品,广泛适用于油库、加油站、油轮、油船、码头、油罐车、机场,分别输送汽油的详细信息概述Overview

上海帕特泵业制造有限公司生产的CYZ-A自吸式离心油泵是根据国内外有关技术资料经消化、吸收、改进后研制而成的最新泵类产品,广泛适用于油库、加油站、油轮、油船、码头、油罐车、机场,分别输送汽油、煤油、柴油、航运等,如改用耐腐蚀机械密封和不锈钢材质还可以适用于化工、制药、酿造、电镀、印染、造纸、电力矿山等,输送介质温度-20℃~80℃,粘度≤100厘泊,含固量可达30%以下.

CYZ-A self-priming centrifugal oil pump is the latest kind of pump developed by us after studying relevant technical data both at home and abroad and also making improvement. It is widely applied in oil houses, gas stations, oil tankers, tank-ships, docks, tank trucks and airports for the transfer of gas, coal oil, diesel oil, and aviation fuel and so on. If adopting the corrosion-proof mechanical seal and stainless steel material, it can also be applied for chemical industry, pharmacy, brewage, electroplate, printing and dyeing, paper making, electricity power, mines, etc. The temperature of its transferring medium ranges from -20℃~80℃;viscosity ≤100 centipoises and solid content below 30%.

特点Features

该泵属自吸式离心泵,它具有结构简单、操作方便、运行平稳、维护容易、效率高、寿命长,具有较强的自吸能力等优点。管路中不需底阀,工作前只需保证泵体内储有定量引油即可。用于油轮或输水船舶上时,可兼作扫舱泵,扫舱效果良好。

该泵是选用优质材料精作而成,密封采用硬质合金机械密封,经久耐用,吐出管路不需要安装安全阀,吸入管路不需要安装底阀,因此简化了管路系统,又改善了劳动条件。

This is a kind of self-priming centrifugal pump, featured by a simple structure, easy and stable operation, easy maintenance, high efficiency, long life, strong self-priming capacity, etc.

The foot valve is unnecessary for the pipeline. Just make sure there is quantitative oil in the pump body before the operation. When used for the oil tanker or the water transport ship, it can be used as the stripping pump meanwhile with good performance in sweeping. It is elaborated with top-grade materials with hard alloy mechanical seal, lasting and durable. It is unnecessary to mount the safety valve for the discharge line and the foot valve for the suction line, thus simplifying the pipeline system and improving the working condition.

工作原理与结构说明Working Principle and Structure Statement

该泵均采用轴向回液的泵体结构。泵体由吸入室、储液室、涡卷室、回液孔、气液分离室等到组成,泵正常起动后,叶轮将吸入室所存的液体及吸入管路中的空气一起吸入,并在叶轮内得以完全混合,在离心力的作用下,液体夹带着气体向涡卷室外缘流动,在叶轮的外缘上形成有一定厚度的白色泡沫及高速旋转液环。气液混合体通过扩散管进入气液回到储液室。此时,由于流速突然降低,较轻的气体从混合气液中被分离出来,气体通过泵体吐出口继续上升排出。脱气后的液体回到储液室,并由回流孔再次进入叶轮,与叶轮内部从吸入管路中吸入的气体再次混合,在高速旋转的叶轮作用下,又流向叶轮外缘……。随着这个过程周而复始地进行下去,吸入管路中的空气不断减少,直到吸尽气体,完成自吸过程,泵便投入正常作业。

在一些泵的轴承体底部还没有冷却室。当轴承发热引起轴承体温升超过70℃时,可在冷却室处通过任意一只冷却液管接头,注入冷却液循环冷却。泵内部防止液体由高压区向低压区泄漏的密封机构是前后密封环,前密封环装在泵体上,后密封环装在轴承体上,当泵经长期运转密封环磨损到一定程度,并影响到泵的效率和自吸性能时,应给予更换。

The pump adopts a pump body structure with axial return of liquid. The pump body consists of suction chamber, liquid storage chamber, turbination chamber, liquid return port, gas-liquid separation chamber, etc. After the pump starts normally, the impeller will suck the liquid in the suction chamber and the air in the inlet line so that the both can mix fully in the impeller. Due to the centrifugal force, the liquid along with the gas flows towards the outer edge of the turbination chamber and then a belt of white foam with a certain thickness and a liquid ring with high-speed rotation come into being on the outer edge of the impeller. The gas-liquid mixture enters the gas-liquid separation chamber through the diffusion tube. Here the lighter gas will be separated from the mixture and rise up and be discharged out of the pump body outlet as the flow speed reduces suddenly. The liquid separated from the gas will return to the liquid storage chamber and enter the impeller again through the return port which mixes again with the gas in the impeller sucked from the inlet line. It then flows towards the outer edge of the impeller due to the high-speed rotation of the impeller……As this process goes round and round, the air in the inlet pipe will reduce constantly until the gas is suctioned out and the self-priming is completed. Then the pump will begin to work normally.

For some pumps, a cooling chamber will additionally be mounted on the bottom of the bearing body. When the bearing heats and its temperature exceeds 70℃,the cooling liquid can be injected through any connection of cooling liquid pipe of the cooling chamber for the circulating cooling. A front-back seal ring structure is adopted in the pump to prevent the liquid from leaking from the high-pressure area to the low-pressure area. The front seal ring is mounted on the pump body while the back seal ring mounted on the bearing body. They should be changed when they are so worn-out that they have an effect on the efficiency and self-priming performance of the pump after the operation for a long time.

|

我要询价

相关产品

- 气动恒差器

- SFD-2002-R数显伺服操作器

- 双芯滤油器

- 不锈钢波纹补偿器(不锈钢波纹膨胀节)

- 高品质皮膜/皮碗加工定做-上海金申 因为专业 所以卓越

- 泵阀配件-专业皮膜订做 上海金申

- 盘型膜片/曲型膜片 专业定做-上海金申

- 橡胶皮碗/皮帽 专业定做橡胶制品-上海金申

- 波纹膜片-专业橡胶制品订做 上海金申

- 橡胶金属组合件-专业皮膜订做 上海金申

- 原装TAS胀紧套 德国赫尔纳(大连)公司

- 代理供应Fischer压力传感器

- Leutert压力指示器

- HNPM 硅胶输送MZR7205微型齿轮泵

- HNPM适合粘稠介质 微量泵

- HNPM 微量泵在机械工程的应用

- HNPM MZR2905用于医用试纸涂层 微量泵

- HNPM MZR2905微量泵

- HNPM用于全自动血型分析仪微量泵mzr-2921-hs-vb

- 美国梅索尼兰现货Masoneilan 偏心旋转阀座圈Camflex II

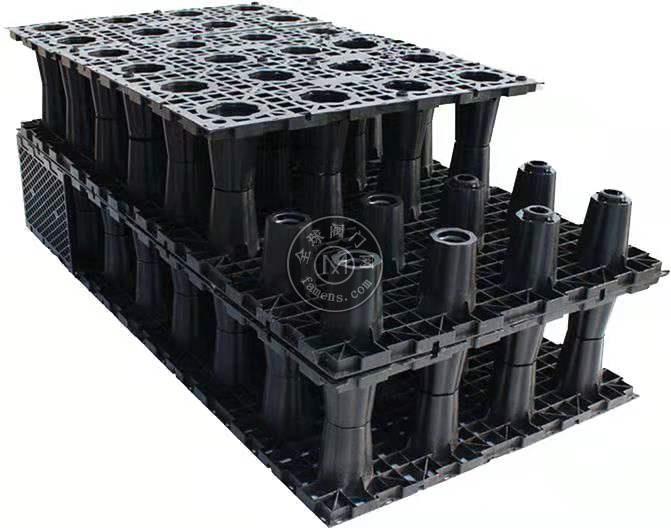

- 龙岩雨水收集系统可有效雨水回收利用